Vacuum casting(Silicone molding) is a great solution for production quality parts without the cost or lead time required for production tooling.

At JR Prototypes, we can cast parts as large and small, everything from headphones all the way up to 2m long car bumpers. We have a massive range of materials available for your projects.

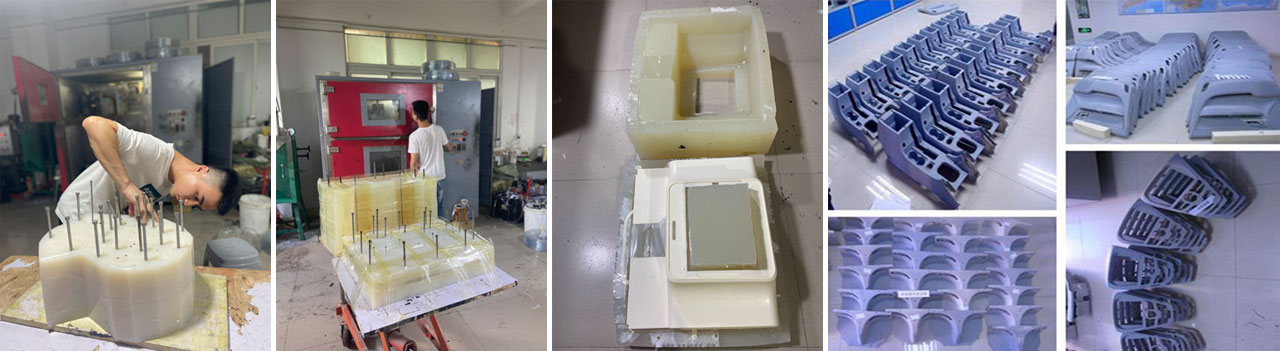

Master model:CNC machined or 3D printed via SLA or SLS.

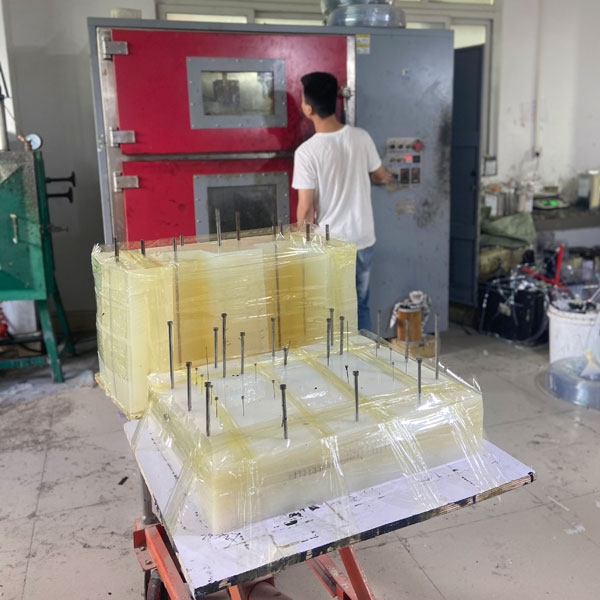

Silicone tool:liquid silicone is poured around the master model and cured. Once dry the master is cut from the mold to leave the cavity.

Castings:the resin is poured into the cavity to create a production like replica

Advantages of Vacuum Casting

1.Good for low volumes

2.Self-coloured parts

3.Low upfront investment

4.Production like parts

5.Huge range of materials

6.Rubber like parts and over molding.